ISPM15 lumber is wood that has been treated to meet the requirements of the international standard for phytosanitary measures number 15 (ISPM15). The standard was developed by the International Plant Protection Convention (IPPC) in order to prevent the spread of harmful pests and diseases through the international movement of wood products.

In order to be compliant with ISPM15, lumber must be heat treated or fumigated. Heat treatment involves heating the wood to a minimum core temperature of 56 degrees Celsius for at least 30 minutes. Fumigation is a process whereby the wood is exposed to pesticide gases in order to kill any pests that may be present.

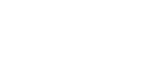

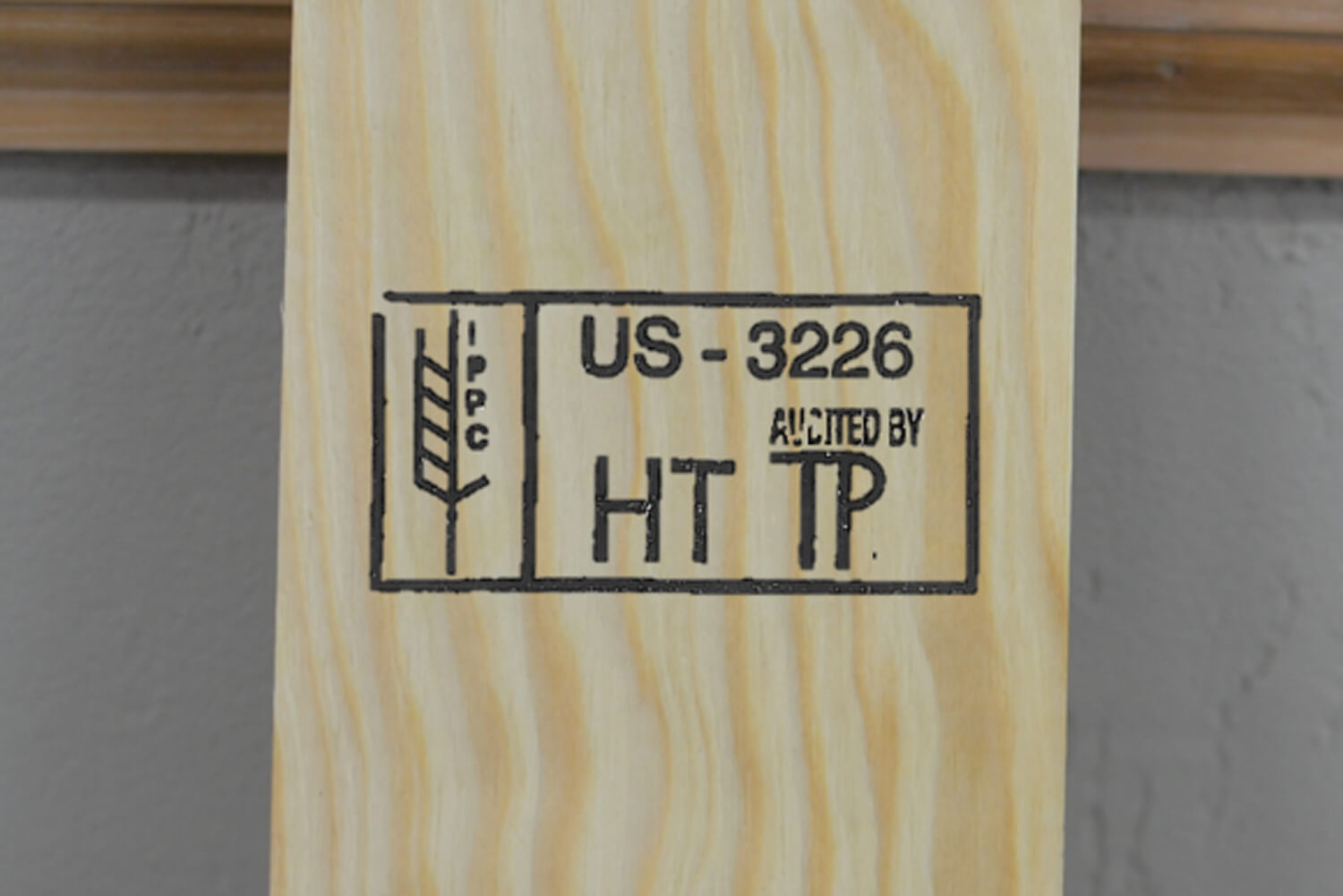

When using lumber that has been heat treated for export to a country that follows IPPC guidelines, it must have an HT stamp prior to an IPPC export marking being applied. The HT stamp alone is not enough to be in accordance with ISPM15 requirements. IPPC markings are required for all wood packaging materials that are being exported to countries that follow ISPM15 requirements to show compliance.

Dunnage is loosely defined as any material used to fill empty spaces in a shipment, such as pieces of wood or cardboard. If you are using dunnage in your shipment, it must be stamped with an IPPC Dunnage stamp. This is to show that the dunnage has been treated in accordance with ISPM15 requirements. Dunnage stamps are intended for loose pieces of material only. It is not recommended to use Dunnage stamped material to build items such as pallets or crates.

Crates, pallets and other assembled wood packaging items have their own specific IPPC marking requirements. The stamp used on these is often referred to as a “Finished Product” stamp, or simply an IPPC Stamp. This stamp indicates that all solid wood components used in that item’s construction fall within regulation. Finished product stamps are applied by those that build the wood packaging item, such as Lodge Lumber or export packing companies that are themselves export stamp holders. They can also be applied by auditing agencies, like Timber Products Inspection. Companies such as TPI, issue IPPC stamps and audit the operations of those that use them to maintain compliance to the regulations. If you are needing to build export compliant wood packaging, but are not an export stamp holder, please consult with Lodge Lumber for your options. It is import to be aware of the regulations of ISPM15 to make sure that your shipment is not quarantined by an inspector and subject to delay, fines or rejection at a port of entry.

Plywood, and other engineered wood products such as fiber board and Oriented Strand Board, are considered exempt from additional treatment processes under IPPC regulations. It is understood that the heat and pressure used in their manufacturing process is sufficient to meet phytosanitary requirements. For that reason, plywood is not HT stamped. Any ISPM15 markings applied to plywood usually are done in crating and packaging applications where solid wood lumber framing is also in use to show inspectors that all wood packaging components used within that assembled item are export compliant.

Lodge Lumber can provide Heat Treatment or Fumigation certificates for any export compliant materials or items that we supply. For any questions on how we can assist with your next export shipment, please contact us at 713-672-6679 or lodgeteam@lodgelumber.com.